1) What is XYSOL? XYSOL is a 100% petroleum-based, exclusive, proprietary product manufactured in specialized fractionation plants in Alberta, Canada. It is not available from any other source. It contains a high percentage of multiple natural aromatic hydrocarbons that are the most effective solvents known throughout the oil industry.

2) FEEDSTOCK: XYSOL is a 100% petroleum based product produced from an exclusive feedstock that is available only from two gas/oil fields found in Alberta. No other feedstock source with the prerequisite composition suitable to manufacture XYSOL has been located in North America. During the manufacture of XYSOL, all C7 and lighter fractions as well as the C19 (and heavier fractions) are removed. Among the C7 and lighter fractions are compounds known to cause the precipitation of asphaltenes when mixed with asphaltenitic crudes. Therefore, products containing these fractions should be avoided for treatment in wells with a significant percentage of asphaltenes. For example, most crudes in the Utah/Wyoming area contain critical percentages of asphaltenes (in the 2% to 8% -range(. It should be noted that any crude oil with an asphaltene content of >0.5% is susceptible to asphaltene precipitation when the oil is exposed to the C7 and lighter solvents, pressure and temperature changes, acid, pump shear etc. The heavier ends are removed to allow XYSOL to more easily and quickly penetrate wax and asphaltene deposits.

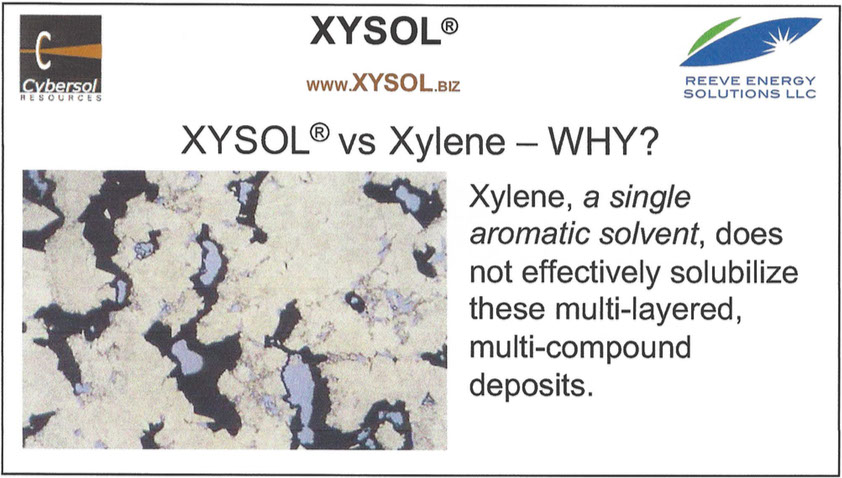

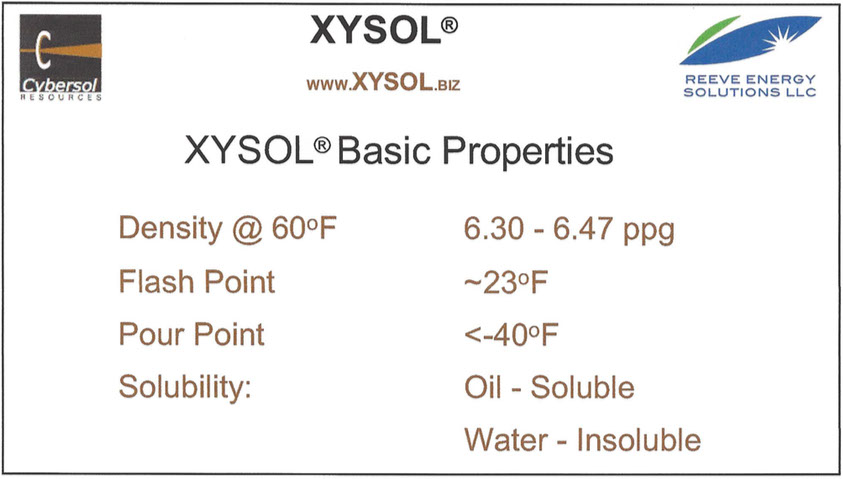

3) XYSOL PROPERTIES: XYSOL contains approximately 30 different naturally occurring aromatic hydrocarbons. And, each type of wax and asphaltene (again, there are many) has different physical and chemical properties. Each respond to the action of solvents (such as aromatic hydrocarbons) in a different manner. One specific type of solvent may or may not dissolve any wax/asphaltene in a well, but by using XYSOL with its —30 different solvents, odds are greatly increased that one or more of these aromatics will be effective. Therefore, XYSOL’s “shotgun” technique is better than attempting to shoot, hit, and solvate a singular problematic wax crystal or asphaltene particle with a single approach product

4) USES:

a. Pumping wells: Removal of waxes and asphaltenes from tubing and rod strings by batching or continuous injection into the annulus.

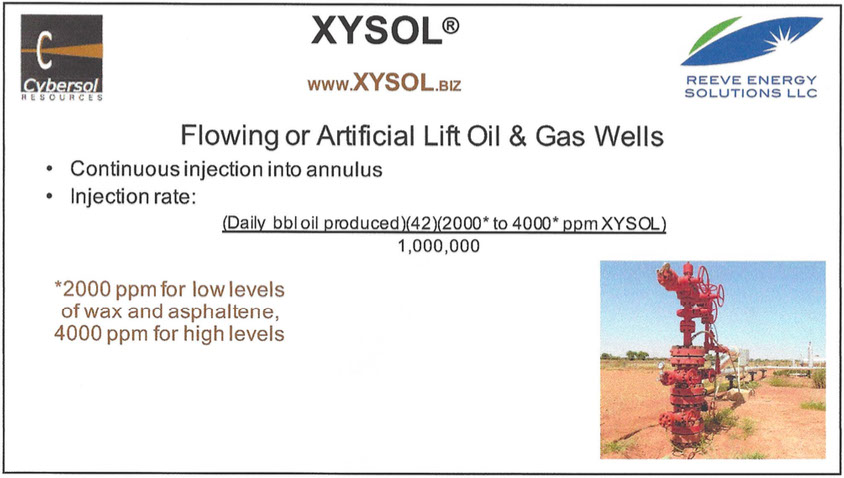

b. Flowing Oil & Gas wells: Usually continuous injection into the annulus.

c. Flowline pressure reduction due to paraffin/asphaltene accumulation: Usually continuous injection at the upstream flowline wellhead connection.

d. Treater problems: Large oil/water interface problems resulting in high BS& W content in produced oil and oil carryover into the salt water disposal system can often be alleviated by continuous upstream injection of XYSOL that effectively eliminates these thick emulsion interfaces.

e. Water disposal systems: Carry-over of wax and tar balls into filters and ineffectiveness of skimmer setups due to sometimes inversion of oil and water wherein the oil (tar balls) sink to the bottom of the vessel is a serious problem that often can be solved by continuous injection.

f. Stimulation of producing formations: XYSOL is often pumped (squeezed) into the formation to clean out the perforations and remove permeability/porosity plugging asphaltene/paraffin deposits in the near-wellbore area. Acid can be used in conjunction with XYSOL to assist in the dissolving of scale and for general formation damage removal.

5) APPLICATIONS AND PROCEDURES:

a. Pumping wells: Depending on the severity of the well’s wax/asphaltene problem, pump XYSOL, at 25% +/- of the calculated empty tubing volume, down the annulus. Then circulate the well within itself for 24 hours or more before being returned to production. XYSOL, with its load of wax and asphaltene held in solution, is pumped out of the well and into the flowline and to the production facilities. A side benefit is that the XYSOL mixture pumped through the flowline will also clean out the flowline and the production facilities.

i. Preventive maintenance: Following the initial cleanup of the downhole tubulars and perforations, each well should be placed on continuous treated regularly (treating time intervals depending on the well’s wax/asphaltene deposition characteristics & severity) by dumping 40 to 80 gallons of XYSOL into the annulus, shutting the well in for 3+ hours to allow the XYSOL to fall to bottom and soak, then returning the well to production.

b. Flowing Oil & Gas wells: The amount of XYSOL required to keep the tubing clear of wax/asphaltene is a direct function of the production rate and the deposition characteristics of the gas/oil. Usually an injection rate in the range of 2,000 – 4,000 ppm is a reasonable place to start. The amount of XYSOL used in ppm can be adjusted up or down depending on the analyses of the results (i.e. have the wax/asphaltene problems been alleviated).

c. The calculation of “ppm” uses the following formula:

XYSOL (gals req.d) = Oil Prod’n (bbls) x 42 x ppm (of XYSOL)/1,000,000

Example:

Oil prod’n = 50 bbls/day, ppm XYSOL to be used = 2000, therefore daily XYSOL required is…

XYSOL (gals) = 50 x 42 x 2000 /1,000,000 = 42 gallons/day

d. Flowline pressure reduction due to paraffin/asphaltene accumulation: XYSOL injection rates of 300 to 3000 ppm are usually required. Use the above equation by substituting the flowline throughput for production.

e. Treater problems: Injection rates should be started in the 500 ppm range and increased or decreased as required to achieve the desired results.

f. Water disposal systems: Injection rates should initially be in the 500 ppm range.

g. Stimulation of producing formations: As the characteristics of producing formations and their production vary dramatically from field to field and well to well, only a generalization of the procedure can be made. In general, 20 to 50 gallons of XYSOL per foot of perforations should be pumped into the formation with zero overflush. The displacement fluid should be clean and compatible crude oil with 10% XYSOL mixed in the first 10 or 15 bbls pumped. The well is usually shut in for 24 to 48 hrs to allow the XYSOL to soak in the formation before it is returned to production. ACID can be used in conjunction with the XYSOL wherein a certain amount of XYSOL is pumped first followed by the acid then a similar amount of XYSOL is flushed to the bottom perforation. Every well should be analyzed and an appropriate program prepared.

NOTE: Before XYSOL is introduced into any producing formation, it is strongly recommended that a cleanup of all downhole tubulars be conducted as indicated in 5 (a) & (b) above, to prevent permeability/porosity reducing contaminants from being introduced into the formation.